[PVC Pipe Automation Plant ] overseas projects were successfully delivered

Liansu involved the entired process of plant planning and design, capacity design, customized program and program implementation, after 7 months of overcoming the impact of the epidemic, the engineering team of Liansu successfully completed the overall delivery of the overseas project of PVC pipe automation factory as scheduled. The project covers the plastic automatic mixing and conveying system in the upstream of PVC pipe extrusion production , PVC pipe extrusion production line equipment, and automatic online packaging system in the downstream of extrusion production.

Project introduction

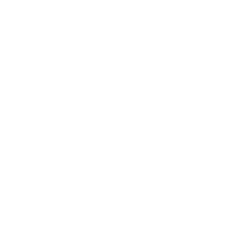

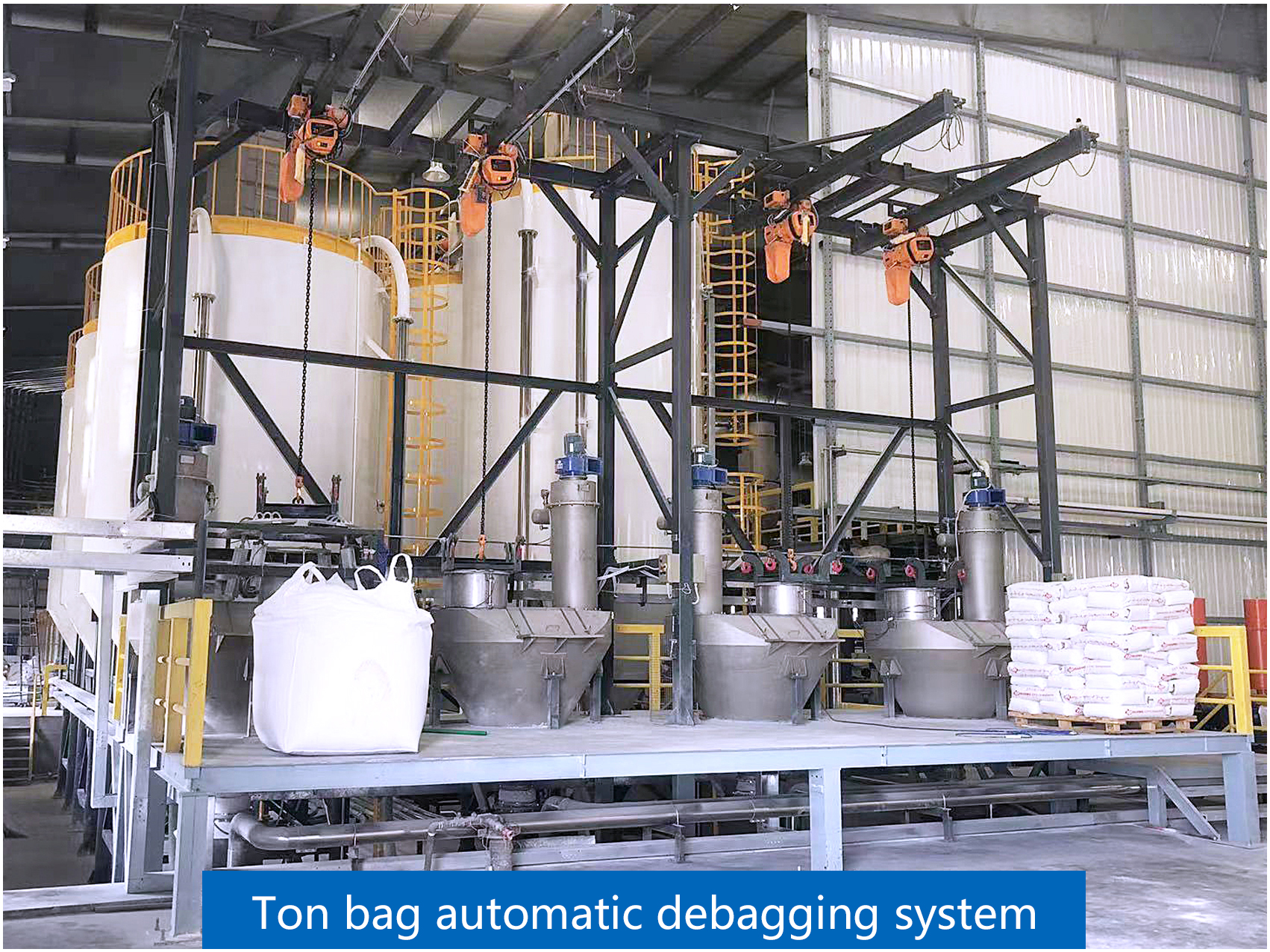

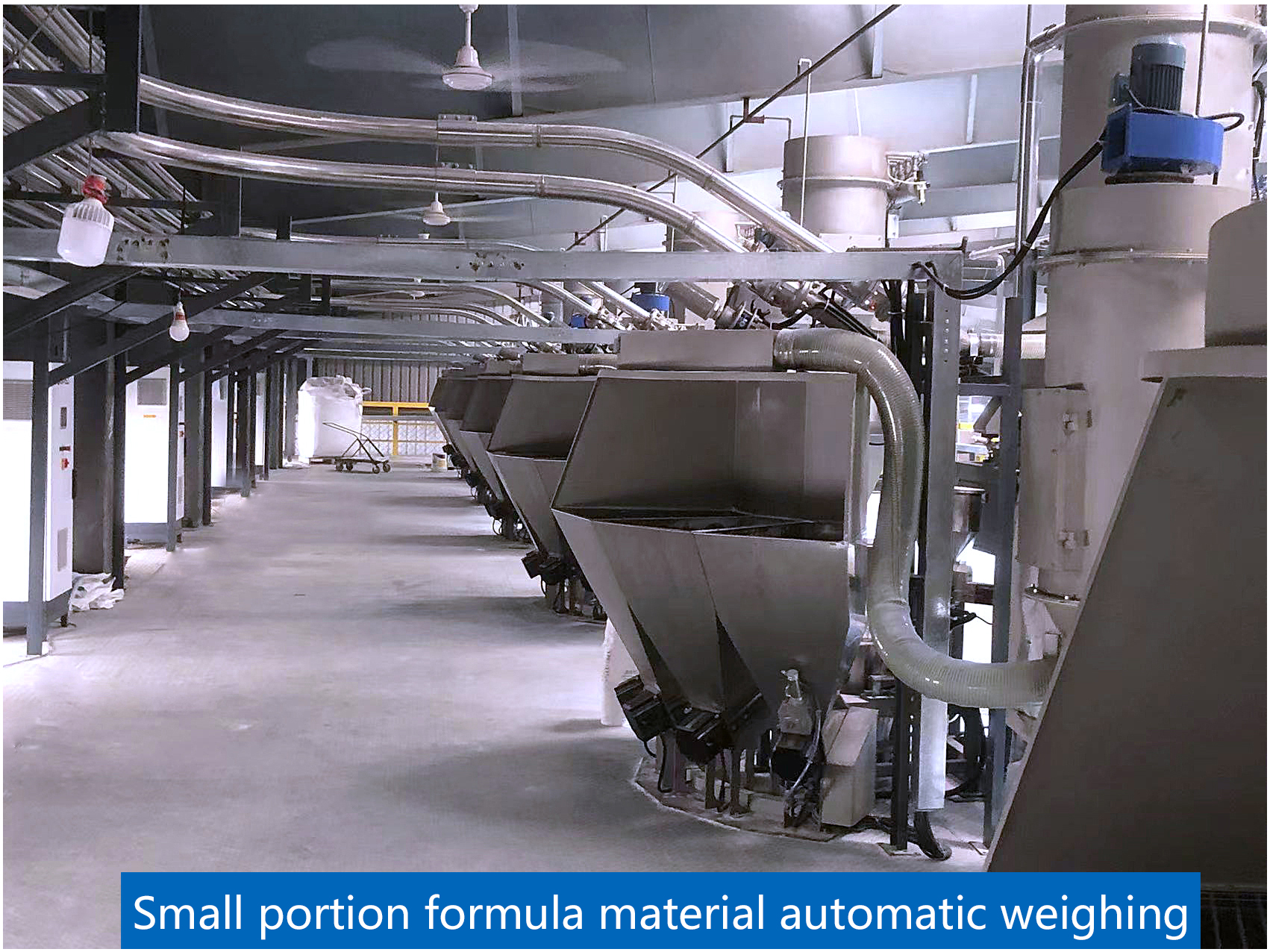

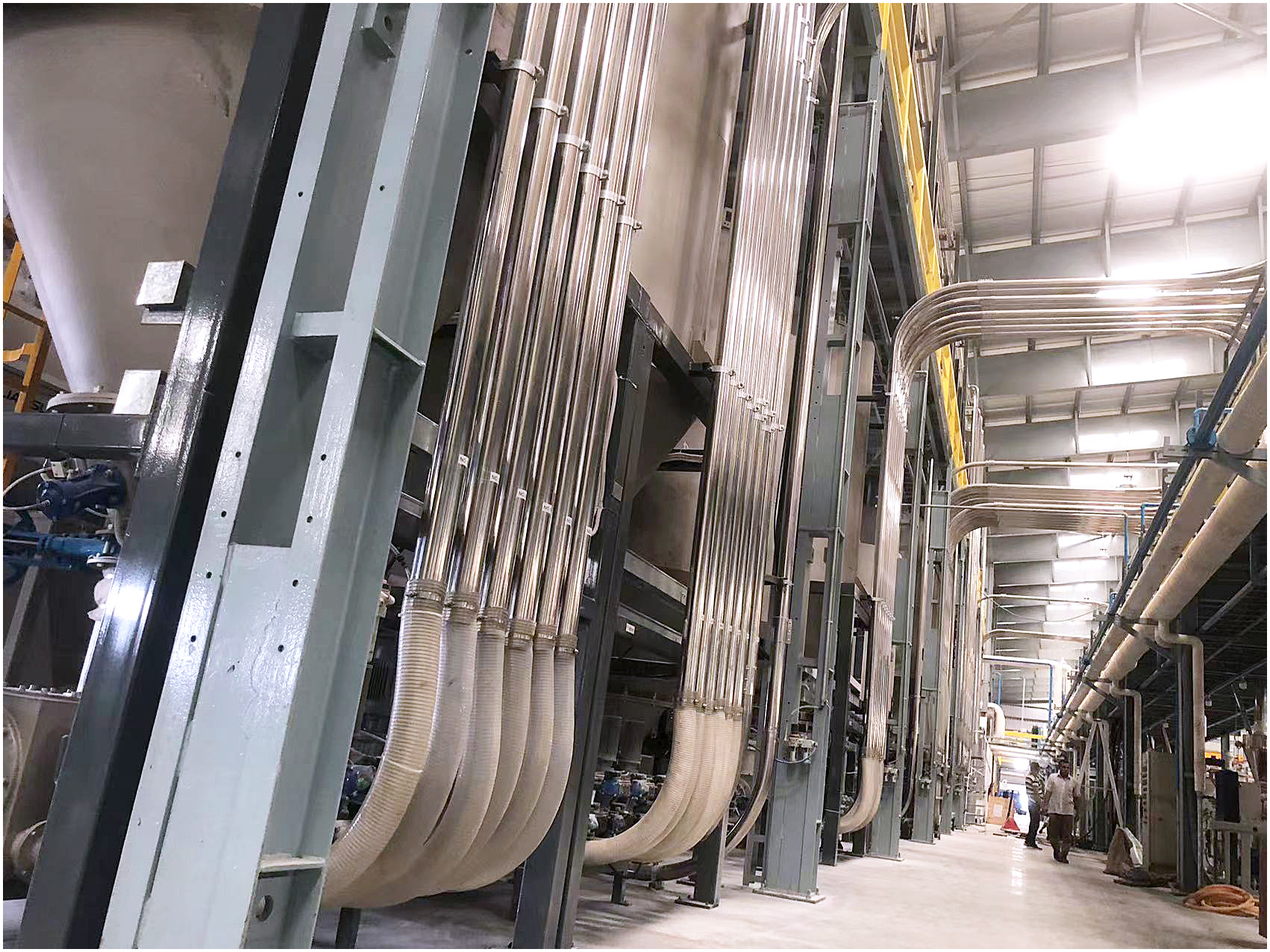

1、Plastic powder automatic compound & conveying system

The system covers the following modules: automatic feeding station for tons bag and small packages of raw materials; indoor storage silo for compound material and automatic weighing system of main material and small portion formula material; high speed compound mixer of raw materials; automatic pneumatic conveying of main material, formula material and compound material.

The difficult points of this project: each extruder need to flexible switch 1 to 3 kinds of formula, further,feeding system meet four kinds of color pipe production”gray, white ,green,red”, according to variety kinds of formula , and different color of the products produced, the whole system design shall met the using requirements of end-users and also control the investment costs, Liansu adopts flexible scheme on different color switch and guide users to optimize the rationality of production schedule, design the best solution for users and the lowest input cost;

The fabrication of large silos and high-altitude pipelines which involved in the project ware all made on site and completed under the guidance of Liansu engineering team. The whole feeding system should realize the overall control communication with the third party brand extrusion equipment and mixer; The operation test is via the transnational remote technical support system .

2、PVC pipe extrusion automatic production equipment

The complete conveying system matched with 28 LIANSU PVC extrusion lines . Such as high-speed four pipe , double pipe and single pipe extrusion. The advantage of Liansu extrusion equipment are energy saving, high efficiency, high output and cover the full range of downstream automatic packaging . In the aspect of energy saving , the main transmission adopts the self-owned brand Hengpu extrusion line special ultra-efficient permanent magnet synchronous motor, combined with Liansu high output screw, PVC pipe processing of the comprehensive energy consumption is as low as 0.09~0.13kwh/kg.

3、Automatic online packaging

The pipe extrusion production line is equipped with online automatic socket equipment ,automatic conveying and automatic online packaging to realizing a true turnkey project of the whole line automation!

The successful delivery of this project is inseparable from our overseas after-sales service engineering team. Every section will be trained and explained, and their professional skills will be handed to customers hand in hand. At the same time, we will follow up the using of equipment in the later period, so that customers are familiar with the use of equipment to ensure the sustainability of user production.

At present, Liansu has established many cases of automatic mixing and conveying system of plastic in Asia, Eastern Europe, Middle East,South America and Africa .We believe that our profession engineer team, project experience and on-site construction ability can make a contribution to your automation factory!