2025-06-17

2025-06-17

888

888

LIANSU offers Wood Plastic Composite(WPC) Pelletizing Solution, which covers wood powder grinding, dosing and mixing, high output co-rotating parallel twin screw extrusion line and FLXCON+ flexible control system to facilitate efficient and stable production.

About wood plastic

Wood plastic compound pelletizing products (i.e. wood-plastic composite granules) are intermediate raw materials made by mixing, melting, extruding and pelletizing wood powder/wood fiber with plastic (such as PE, PP) and other additives. They have the advantages of both natural fibers and plastics and are widely used in outdoor building materials, garden landscaping, packaging and logistics, such as floors, plank roads, wall panels, pallets, etc. They are anti-corrosion and moisture-proof, weather-resistant and durable, and maintenance-free.

Grinding

The stability of wood plastic particles begins with raw material processing. LIANSU grinding system is equipped with rough grinding, fine grinding, and screening equipment to achieve uniform particle size control, stable moisture content at around 3%, and a single-line output up to 320kg/h. The entire line adopts a closed structure, which significantly reduces dust emission, improves the cleanliness of the production line and operational safety, and provides reliable protection for subsequent mixing and extrusion.

Dosing and mixing

The system can realize automatic dosing of various raw materials required in the process of wood plastic compound pelletizing, including wood powder or wood fiber powder, PE/PP granules, silicone oil, soybean oil and other liquid additives and various auxiliaries. After dosing, the raw materials enter GRH500G-LH1500G high-speed compound mixer for efficient and uniform mixing. The mixing capacity is as high as 2 tons/hour, and the unit energy consumption is as low as 25kWh/t with high efficiency and energy saving.

Extrusion

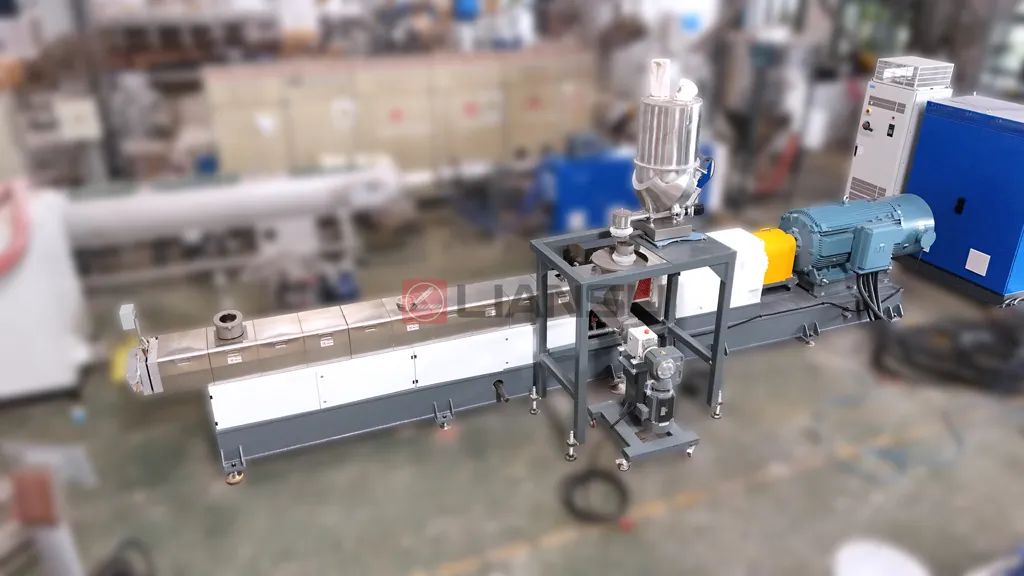

The production line adopts LS93M-44D high output co-rotating parallel twin screw extruder, with large L/D screw design and high torque gearbox, which is optimized for stable extrusion of high-filler wood powder raw materials. It is equipped with a powder loss-in-weight feeder with excellent anti-bridging performance to achieve accurate raw material supply. The production capacity of the whole line can reach 1.2 tons/hour, and the unit energy consumption is as low as 70kWh/t with high efficient output and energy control.

FLEXCON+ flexible control system

The electronic control based on IPC architecture, integrated control and data analysis system, not only has a good equipment operation experience, but also has powerful data collection and analysis functions.

More details, pls contact: +86-18028101014 (Tel/WhatsApp).