2025-06-09

2025-06-09

1385

1385

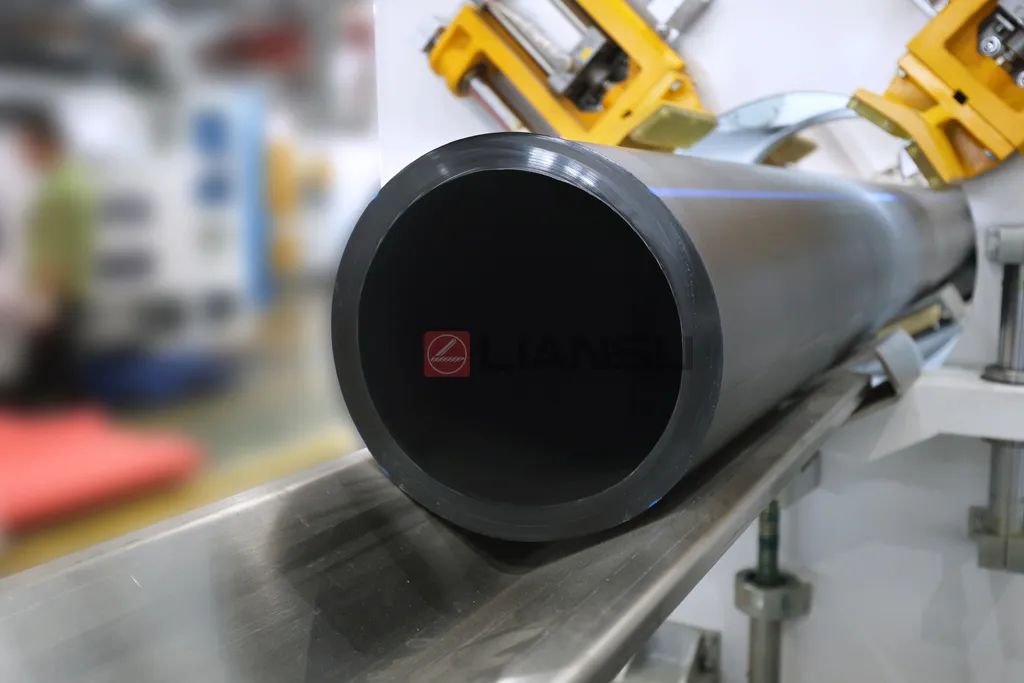

LlANSU offer size range from 20~1600 mm with high speed hdpe pipe extrusion machines suitable for mono layer and multi layer pipe extrusion. Hereunder we will like to introduce LSP-450 HDPE pipe high speed extrusion line, pipe size range from 110-450mm with warranty output 1200kg/h. LlANSU offer a completed system from material debagging to dosing and extrusion.

Material debagging and dosing

LIANSU equipped with Mconvey Automatic debagging system in the upstream of the extrusion line to realize automatic bag opening and feeding of raw materials, greatly improving feeding efficiency and reducing labor intensity. And it is equipped with a multi-component Gravimetric blender to accurately dose and mix various materials, ensuring formula stability and product consistency, and helping the entire line to achieve intelligent and refined production.

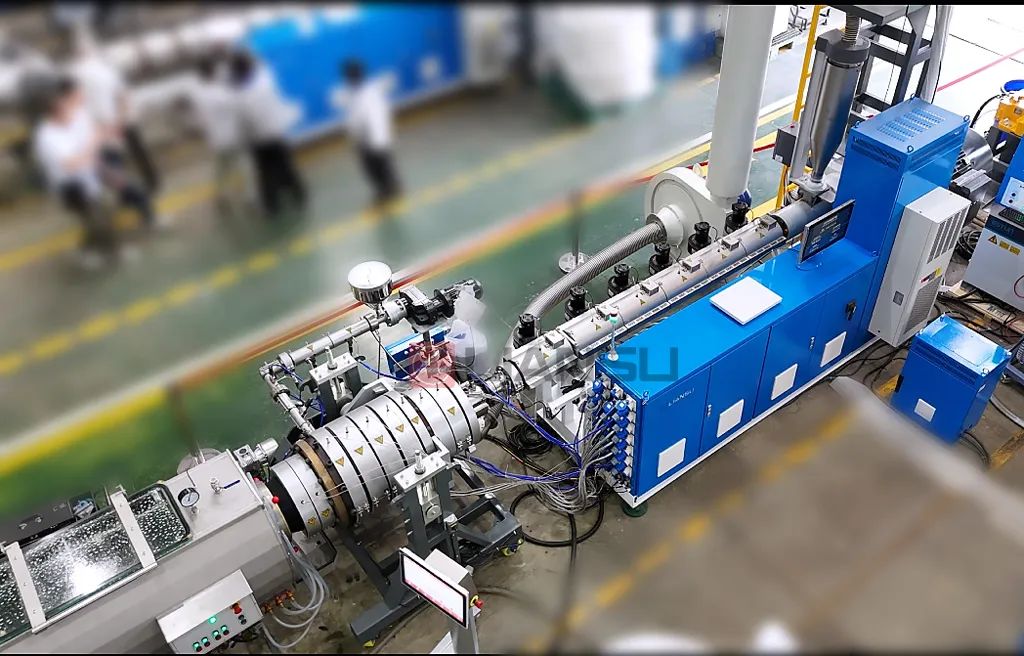

High output and stable melt temp

Adopt LlANSU 40H Single Screw Extruder, ensure high speed and controllable melting temperature, high out and less power consumption. LlANSU Pipe Head with vacuum cooling, high output and reduced cooling length of entire line.

Vacuum closed-loop control

Vacuum control adopts automatic negative pressure closed-loop control system to ensure rapid pipe forming , shorten the required cooling tank length, greatly increase pump motor life-cycle, realized over 50% energy saving.

Haul off

Haul off unit adopts "one-to-multiple" servo synchronous control, one inverter driver drives multiple permanent magnet synchronous servo motors simultaneously with speed ratio range exceeding 50 times, stable pulling force. Winch device also adopt servo control accurate synchronized with hauling speed, reducing waste percentage.

Cutter

LIANSU developed Fully automatic swarfless cutter from 20~2700mm and is suitable ultra-thick pipe cutting up to 150mm, realized "one-button automatic switch diameter change" , reduce machine downtime, less labor force and reduce maintenance.

Obtain more product info,pls contact : +86-18028101014(wechat/whatsApp).