2025-06-23

2025-06-23

1024

1024

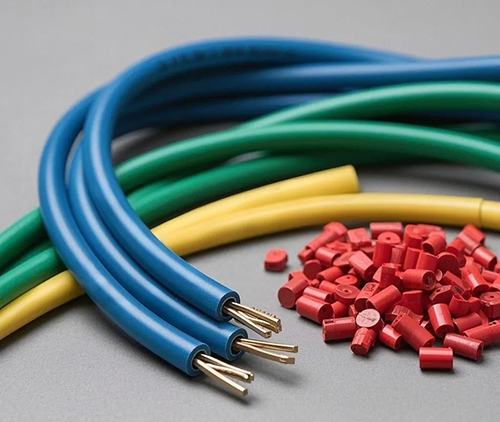

As the demand for PVC cable materials grows, how to achieve efficient, stable, and data-based PVC cable material compound pelletizing production has become the focus of the industry. LIANSU offers a turnkey compound pelletizing solution for cable materials.

Centralized control+ high output

Market capacity requirements range from 500kg/h to 3000kg/h, and the requirements for the process control capability, system stability and automation of the equipment are constantly improving.

Process requirements

PVC cable material formula is complex, include PVC resin , filler, plasticizer stabilizer and other addititives. in production processing, there are several typical challenges:

High precision requirements for formula: The main and auxiliary materials need to be accurately weighed and automatically dosed.

Mixed material consistency affects product performance: It is necessary to ensure that there is no segregation and dead corners in the mixing process.

The production process is unstable: Extrusion temperature control and shear stability determine product consistency.

Environmental protection + cost reduction pressure: The system needs to reduce energy consumption and labor input.

Solution

Dosing

Mconvey, a brand of LIANSU, provides automatic dosing solutions for various material. Main materials such as PVC resin are dosed by weighing scale, liquids such as plasticizers are accurately controlled by liquid dosing feeder, and different auxiliary materials are accurately dosed according to the formula through multi-component powder formula weigher to ensure that the proportion of each batch of materials is accurate and consistent, improve product quality stability, and realize formula data recording and traceability.

Mixing

After dosing, the materials enter the high-speed compound mixer for mixing. The high-speed compound mixer can quickly and evenly mix the materials to meet the strict requirements of PVC cable materials for mixing quality. The mixing process is highly automated, which can significantly improve production efficiency and avoid errors caused by human intervention.

Compound pelletizing

Liansu provides high-stability parallel twin screw extruder based on the characteristics of PVC cable materials to ensure uniform shearing and sufficient plasticization. Pelletizing adopts an air-cooling system, equipped with patented spiral cooling technology, internal and external double cooling channels, high cooling efficiency, and supports large output. The equipment is maintenance-free, low-noise, and fully enclosed structure to ensure environmentally friendly production. It is stable and reliable and is suitable for high-standard pelletizing needs of cable materials.

Packaging

25kg jumbo bag packaging machine can realize weighing, bagging and sealing, which is easy to operate and improves packaging efficiency.

More details, pls contact: +86-18028101014 (Tel/WhatsApp).