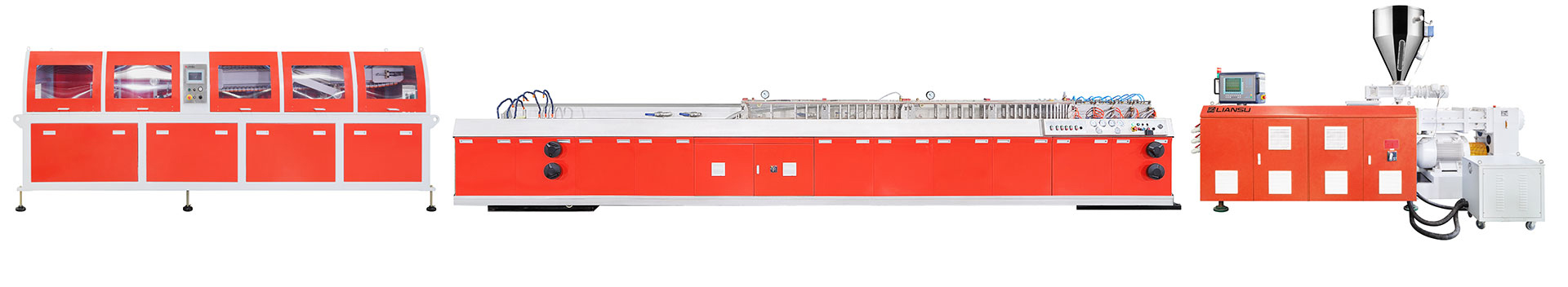

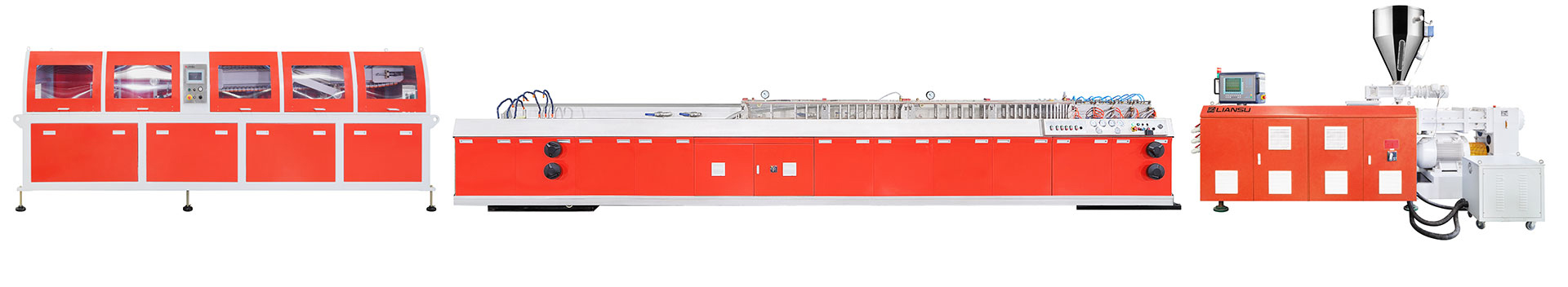

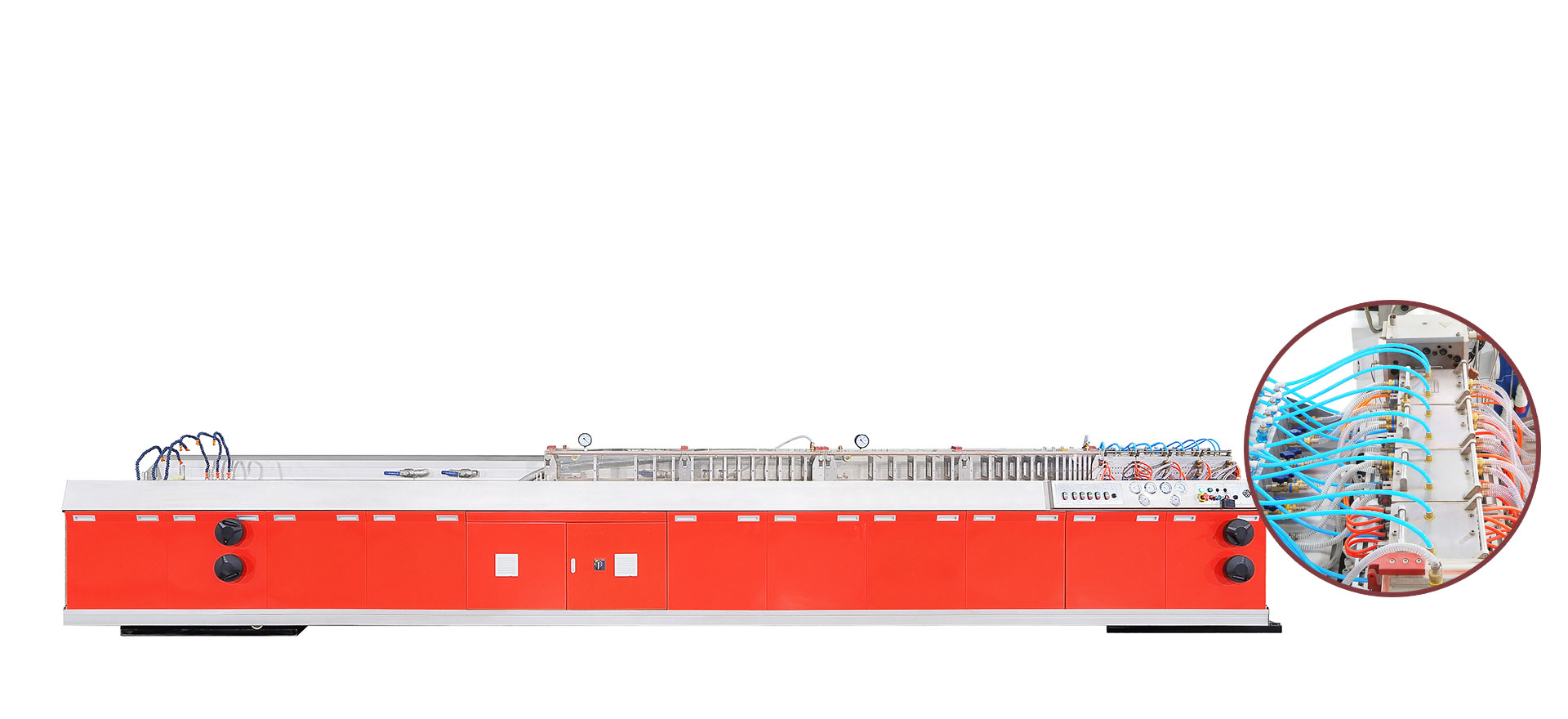

LS-PVC Window Profile Production Line

12

MAX HAULING SPEED(m/min)

220

TOTAL INSTALLED POWER(kw)

450

MAX OUTPUT(kg/h)

LS-PVC Window Profile Production Line

12

MAX HAULING SPEED(m/min)

220

TOTAL INSTALLED POWER(kw)

450

MAX OUTPUT(kg/h)

Product Advantage

Low-shear, high torque and large L:D ratio, guaranteeing stable extruding.

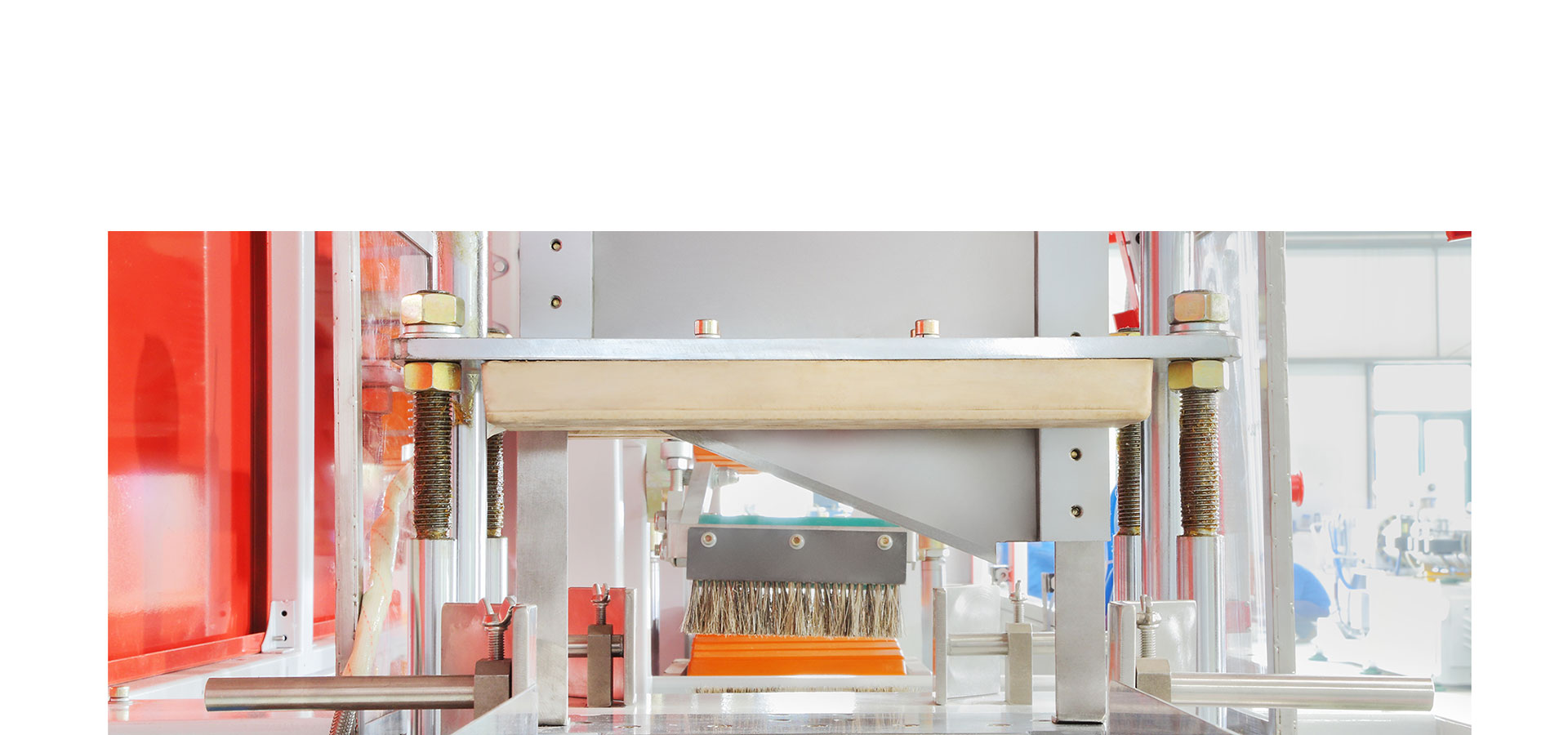

High efficiency, energy saving, closed-loop structure of water channel and easy operation design.

An equitable vacuum channel, water in and out distribution network.

Low-shear, high torque and large L:D ratio, guaranteeing stable extruding.

High efficiency, energy saving, closed-loop structure of water channel and easy operation design.

An equitable vacuum channel, water in and out distribution network.

Extruder

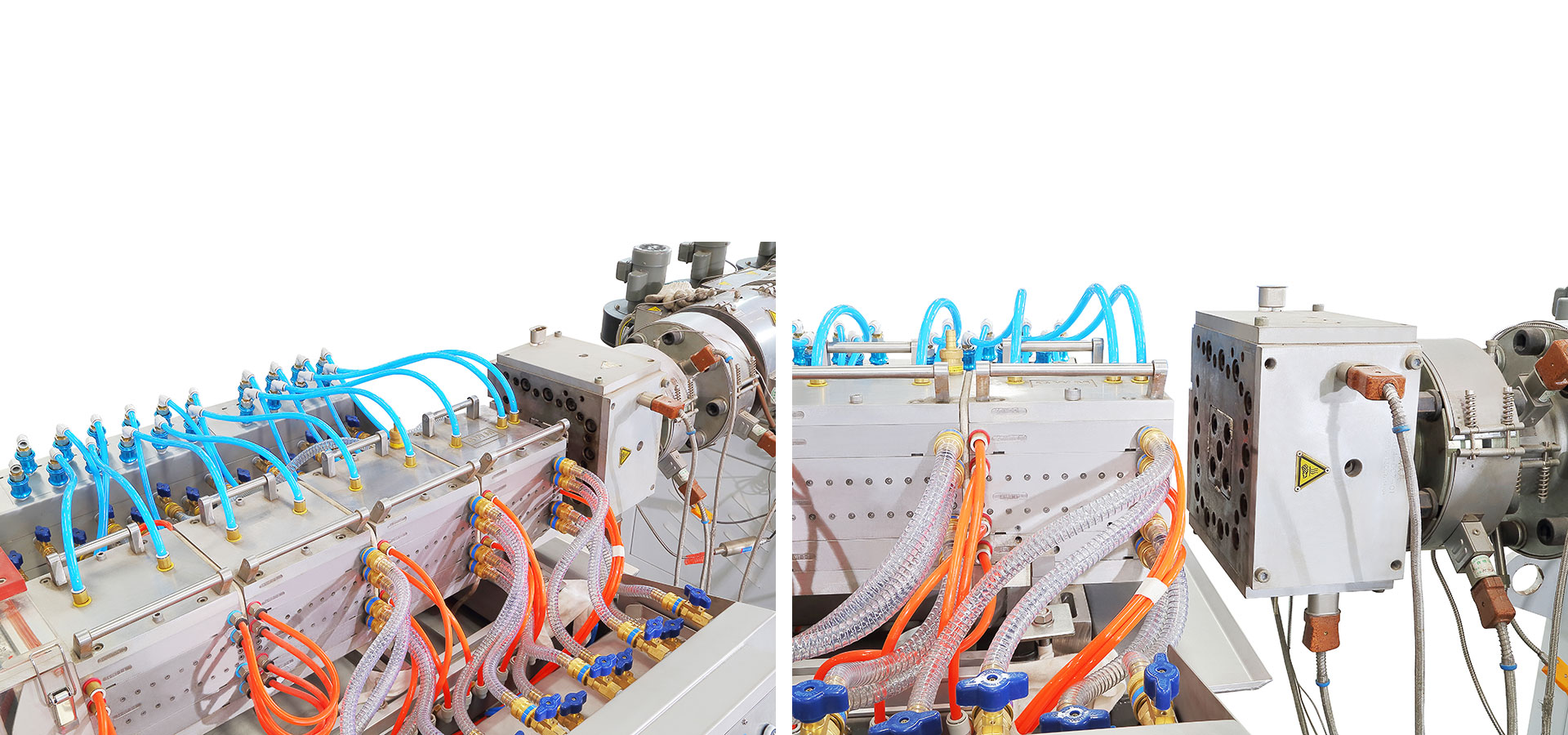

Mould Design

Mould Design

Calibration Table

Calibration Table

Haul-off

Haul-off

Cutter

Cutter

Technical Data

* Test and accept based on Liansu standard formula

Sample