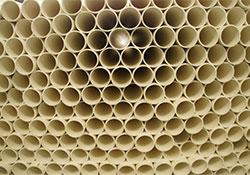

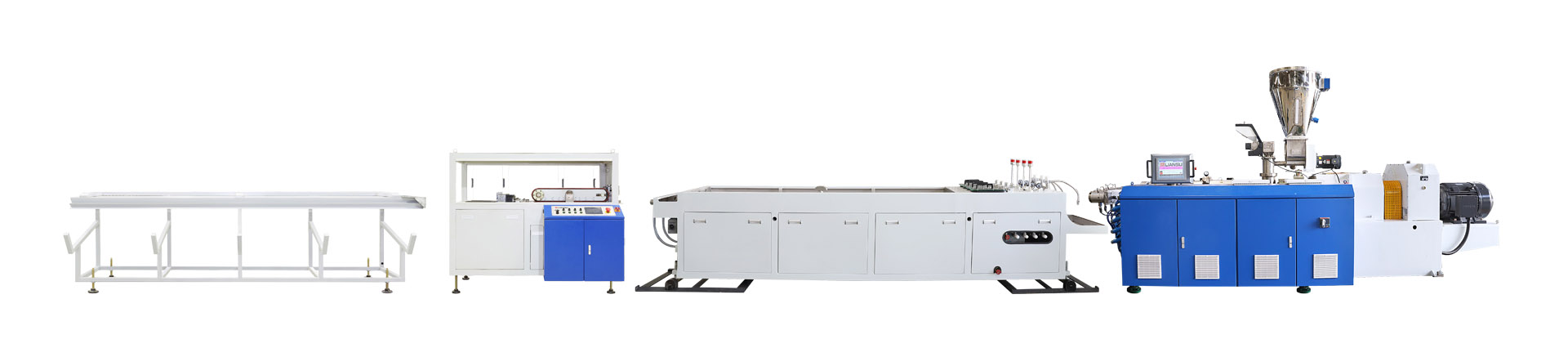

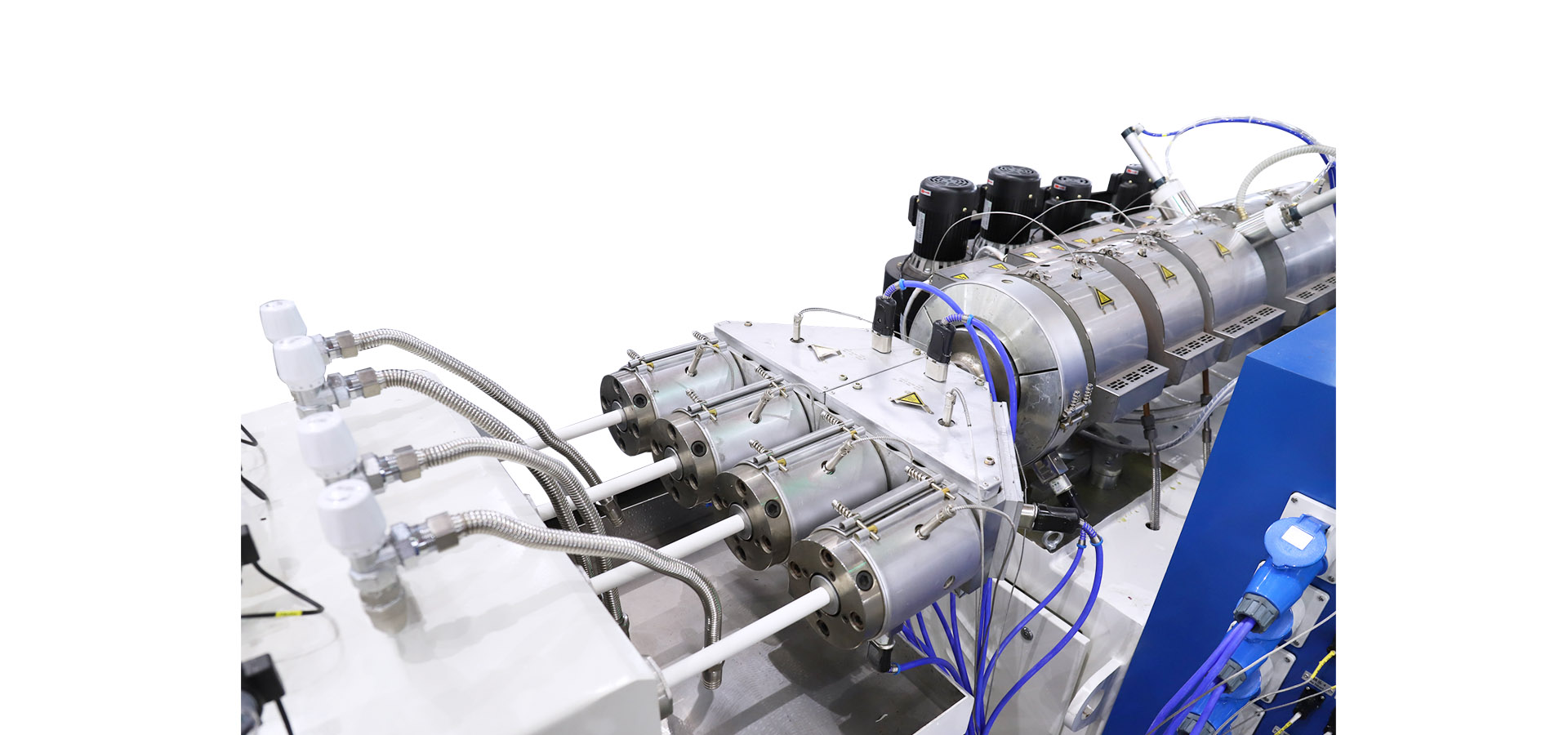

PVC Four Pipe Production Line

Ø16 -Ø32

PIPE RANGE(mm)

18

MAX HAULING SPEED(m/min)

150

TOTAL INSTALLED POWER(kw)

450

MAX OUTPUT(kg/h)

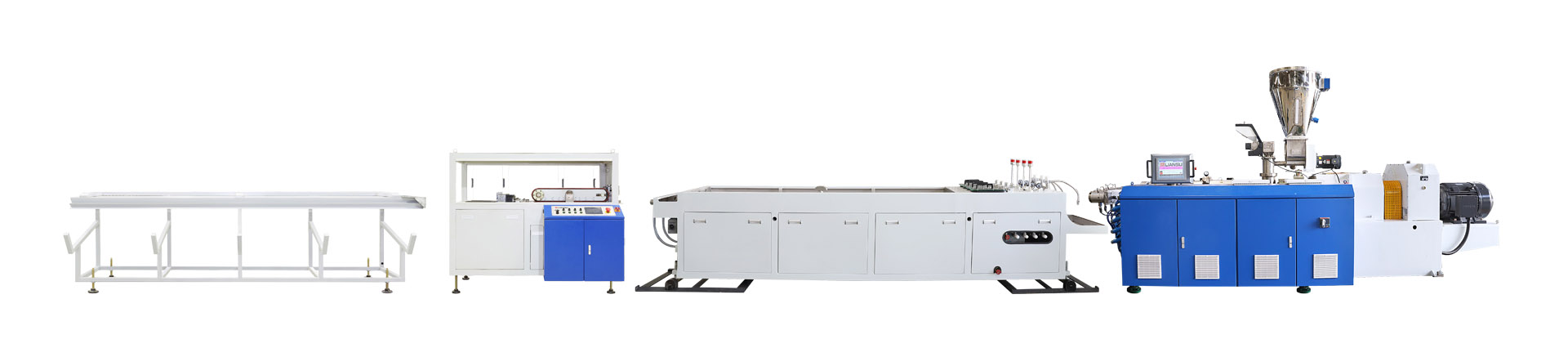

PVC Four Pipe Production Line

Ø16 -Ø32

PIPE RANGE(mm)

18

MAX HAULING SPEED(m/min)

150

TOTAL INSTALLED POWER(kw)

450

MAX OUTPUT(kg/h)

Product Advantage

The extruder is equipped with online color powder weighing, which can change colors flexibly.

Vacuum adopts frequency conversion closed-loop control, energy-saving and stable.

Equipped with online automatic packing mechanism, efficient and labor saving.

Production data acquisition and analysis system can be selected to realize transparent production management.

The extruder is equipped with online color powder weighing, which can change colors flexibly.

Vacuum adopts frequency conversion closed-loop control, energy-saving and stable.

Equipped with online automatic packing mechanism, efficient and labor saving.

Production data acquisition and analysis system can be selected to realize transparent production management.

Extruder

Mould Design

Mould Design

Vacuum Tank

Vacuum Tank

COMBO DESIGN OF HAULING + CUTTER + PACKING

COMBO DESIGN OF HAULING + CUTTER + PACKING

Packing

Packing

Technical Data

* Test and accept based on Liansu standard formula

Sample