LIANSU is devoted to plastic pipe extrusion processing and continuously promotes technological innovation and product development. In recent years, as the pipe industry has increasingly higher requirementsfor environmental protection, durability and production efficiency, molecularly oriented polyvinyl chloride (PVC-O) pipes have gradually become the new trend due to their excellent performance.

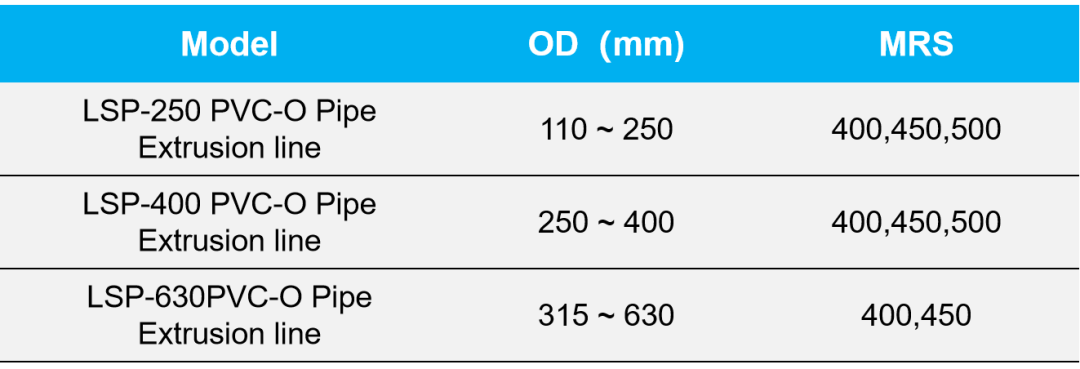

LlANSU has successfully developed size range OD110~630mm PVC-O pipe extrusion line, providing customers with stable performance, energy-saving and environmentally friendly water supply pipe solutions to meet market demand.

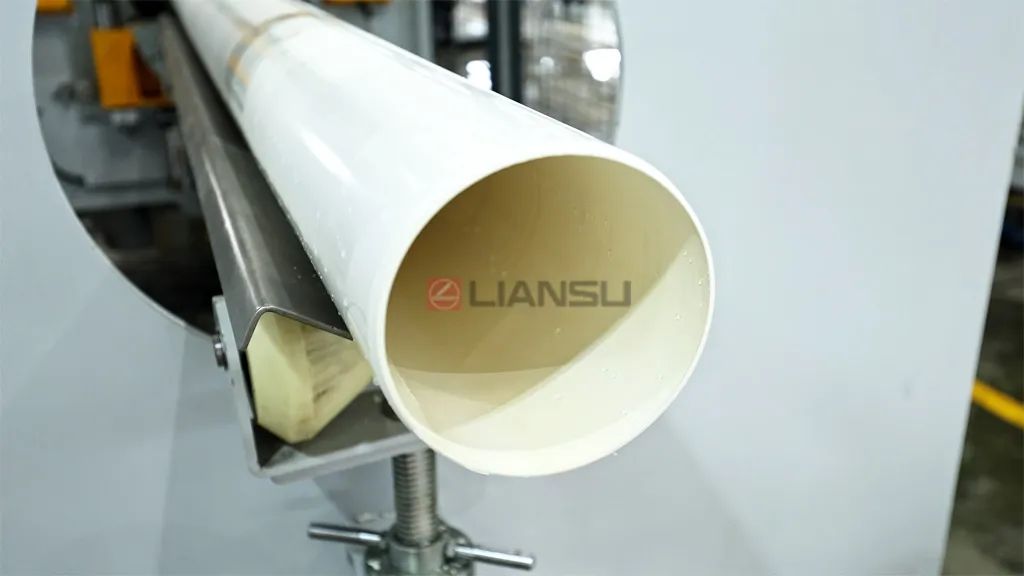

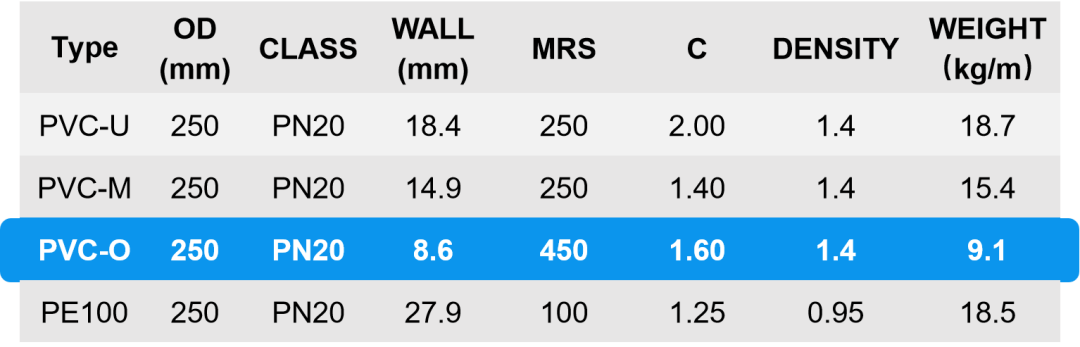

PVC-O Pipe Introduction

PVC-O pipe is a high-performance plastic pipe made by a special directional stretching process. It is widely used in municipal water supply, agricultural irrigation, industrial fluid transportation, mining pipe network and sewage drainage system. Compared with traditional PVC pipe, PVC-O pipe has a tighter and more regular molecular structure and significantly improved performance. The features are as follows:

✔High flow capacity

✔High impact strength

✔High toughness

✔Excellent damage tolerance

✔Light weight

✔Material and energy efficient ,more environmentally sustainable

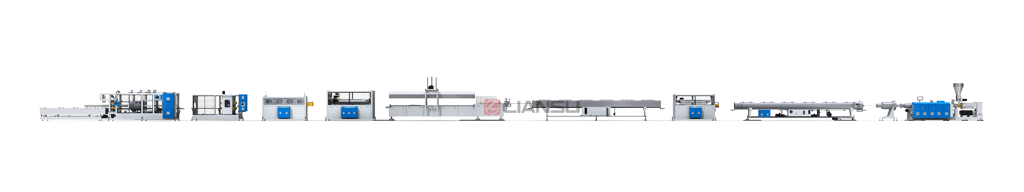

LIANSU PVC-O Pipe Extrusion Line

LIANSU PVC-O Pipe Extrusion Line

The production process of PVC-O pipes is complex and requires extremely high reliable equipment, raw materials and processing control. The production of PVC-0 requires the pipe to be stretched in both axial and radial directions to rearrange the PVC molecular chains in a specific direction. The directional stretching process has very strict requirements on temperature, stretching speed and ratio. Any slight deviation will lead to uneven molecular orientation or pipe rupture.

LIANSU uses online production technology to realize biaxial directional pipe manufacturing. The production line is equipped with specially designed and optimized professional equipment for the production of PVC-O pipes, including: extruder and pipe head, vacuum tank, haul off unit, oven, heating furnace, stretching device, cutting machine and online socket machine. The production line provides full-process integrated control system.

LIANSU offers production lines to produce pipes that comply with ISO 16422 or with required national standards. LIANSU production lines can be tailored to produce product, strength up to MRS 500. Pressure classes up to PN25. The lines can also be tailored to produce product at lower MRS and pressure classifications.

For more product information, welcome to contact us: +86-18028101014.