2025-07-08

2025-07-08

729

729

In plastic pipe manufacturing industry, "improving efficiency and reducing costs" is an urgent need for most manufacturers. By improving equipment operating efficiency, increasing production flexibility, and reducing production costs, we can gain more initiative in the current competitive market. LIANSU always focus on customer needs to help customers improve the product competitiveness.

Hereunder we will like to introduce the high speed extrusion solution for PVC pipes, LSP-160 drainage pipe extrusion line, pipe size range from 90-160mm with output of up to 1400kg/h. This solution not only improves output, but also takes into account product quality and production stability. At the same time, it supports flexible switch formulas online to reduce comprehensive production costs.

Flexible manufacturing

According to required formula during actual production, LIANSU provides PVC Pipe flexible solution to change the traditional production way, realizes "online dosing and mixing" . Extruder is equipped with multi-component loss-in-weight combo, according to the set formula proportion, accurate online dosing and mixing dry blend material , extra calcium carbonate, additives, pigment, it greatly reduce time and production cost on formula adjustment.

Multiple materials are dosed and high-speed mixing on line and feed to extruder, mixing energy saving reaches 20kWh/ton compare to traditional way of mixing.

Loss in weigh combo can realized formula switch on line , which saves time and labor in changing materials and reduces material waste.

Efficient and stable high speed production

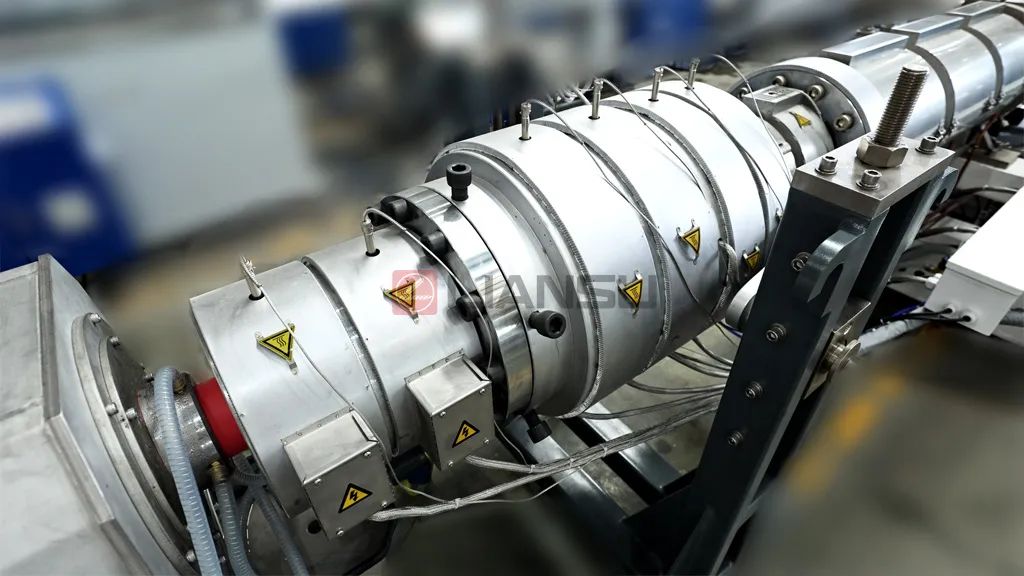

Parallel twin screw extruder adopts 36 L/D screw design, ensure high output, stable melt temp.

The pipe head adopts double layer distribution structure,low back pressure under high output extrusion and it perfectly eliminates diversion marks.

Vacuum Cooling adopts patented design, increase cooling area and cooling water utilization, cooling efficiency is 20% higher than traditional nozzle spray cooling.

Online socket equipment, reach line speed 16 m/min ,online rubber ring feeding, synchronize with cutter to switch required pipe length.

Liansu will continue to focusing on flexible and efficient production to help customers stand out in the fierce competition.

For more info, pls contact us:+86-18028101014(wechat/whatsApp).