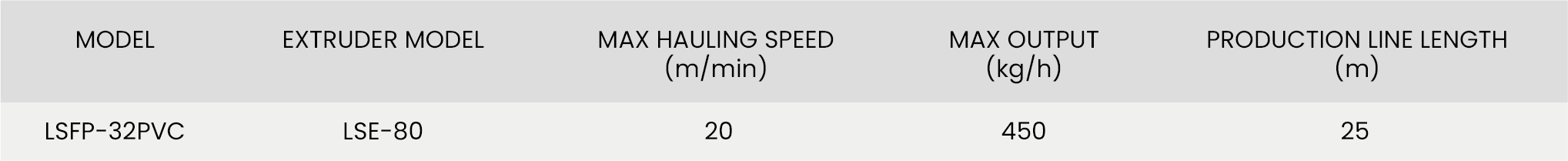

Four strand extrusion for electric conduit tube.Downstream cutter adopt swarfless cutting,with online belling and automatic bundling and packaging equpment,saving space and high output, less power consumption.

Size range(mm):

Max output(kg/h):

Material:

Brochure Download

Brochure Download