2025-07-17

2025-07-17

759

759

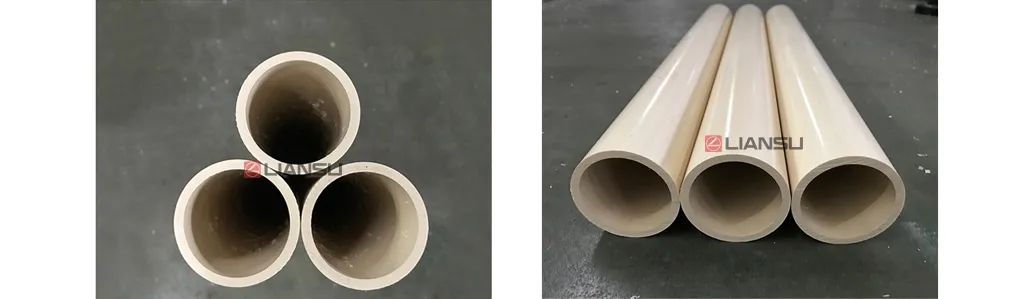

With the growing demand for high-performance pipes, CPVC (chlorinated polyvinyl chloride) pipes are widely used in fire protection pipe systems, industrial pipe systems, hot and cold water piping systems and other fields due to its excellent high temperature resistance, corrosion resistance and flame retardancy.

With the requirements of CPVC composite materials on accurate temperature control and stable plasticization, LIANSU provides different machine model from OD16 to 315mm CPVC pipe extrusion lines to achieve stable and efficient production.

Extrusion line Introduction

LSP-315 CPVC pipe extrusion line

Size range: 4" to 12"

Product output: 350-400kg/h

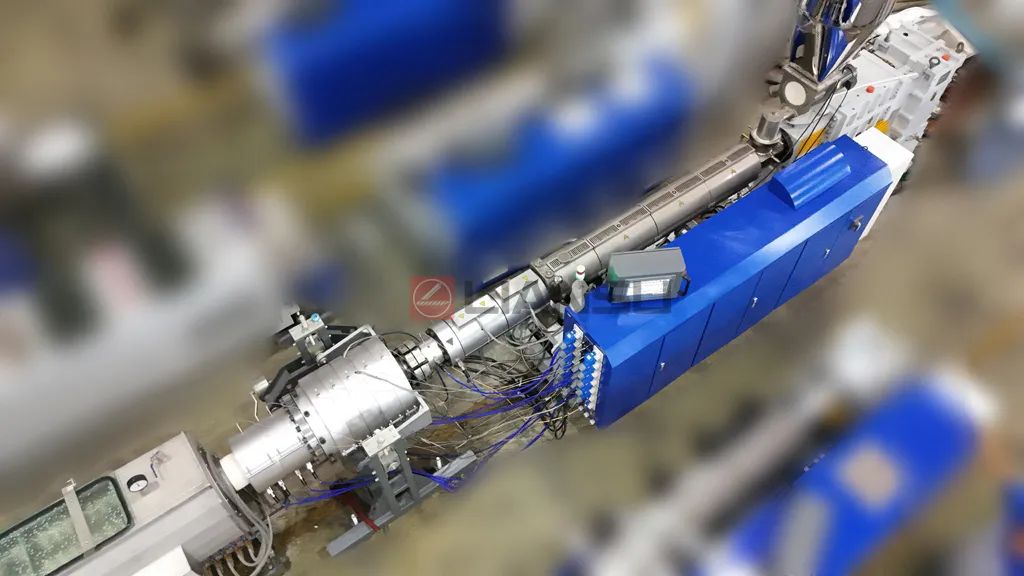

Extruder

It adopts optimized screw designed for CPVC composite materials, and combines with a accurate temperature control system to achieve stable plasticization and efficient extrusion. The drive system uses permanent magnet synchronous servo motor, which can reduce 1~2 power levels compared to traditional AC asynchronous motors, effectively reducing energy consumption .

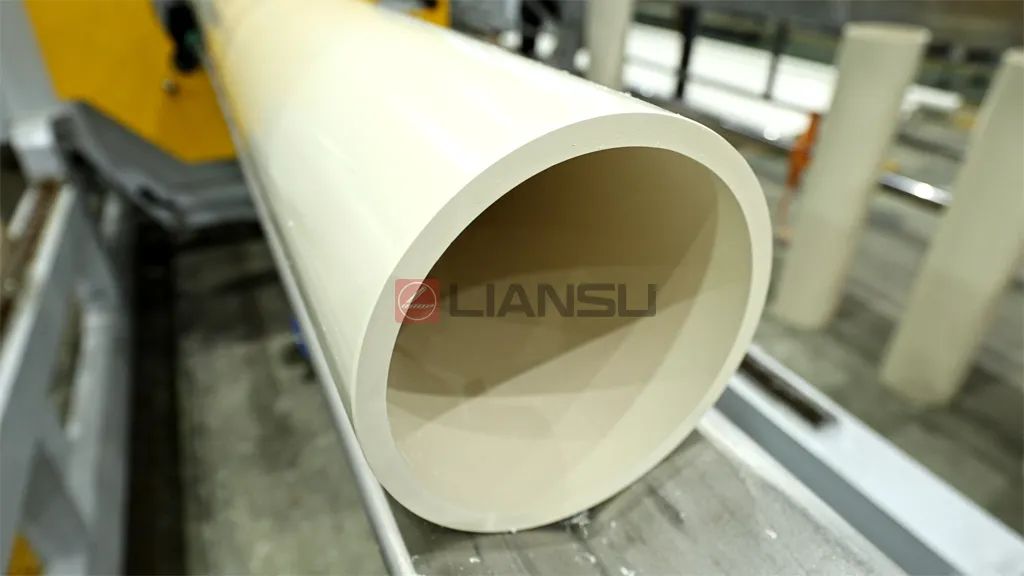

Pipe head

It adopts optimized flow channel design to ensure high extrusion capacity and reasonable compression ratio, effectively improving the dimensional stability and surface quality of the product. The structural design focuses on modularization and convenience, which is convenient for quick installation, disassembly and daily maintenance, and improves mold change efficiency.

Vacuum tank

It adopts an independent control system and is equipped with a negative pressure closed-loop automatic adjustment function to ensure stable vacuum and effectively improve the sizing and surface quality of pipes. At the same time, through optimized structure and noise reduction design, the operating noise is reduced by more than 30dB, and the energy saving range can reach 30%~85%.

Haul off

It adopts a permanent magnet synchronous servo drive system to achieve a wide range of precise speed regulation, and flexibly adapt to the different traction requirements of small to large specifications of pipes. Each crawler is precisely synchronized with more stable operation and more sensitive speed regulation , providing continuous and stable power support for the production.

Cutter

Equipped with an efficient, precise, low-noise swarfless cutting machine, the cutting process is independently controlled throughout, and it responds quickly to the production , which not only increases the output , but also avoids the debris and dust caused by traditional cutting, creating a cleaner and more environmentally friendly work site.

Choosing mature and stable equipment is the first step to realized efficient production. LIANSU CPVC pipe extrusion line has been successfully applied in many projects. Welcome to contacts us +86-18028101014 to obtain customized solutions and more application cases.