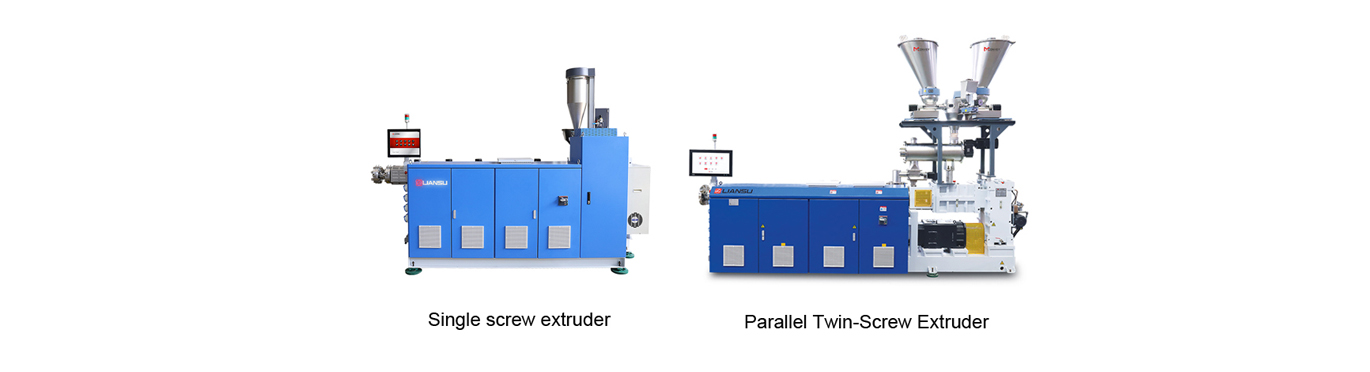

Long LD Screw Application

Liansu developed long L/D screw design on PVC Parallel Screw extruder and HDPE Single Screw Extruder in order to improve extrusion efficiency and performance. HDPE pipe extrusion, LIANSU adopts latest optimized design of 40L/D high-efficiency single-screw extruder + Sprial feedbush and spiral barrel, guarantee high output and constant melt temperature.PVC pipe extruder, LIANSU adopts 36 L/D ratio parallel twin-screw design, ensures high output and good material shear and plasticization quality.

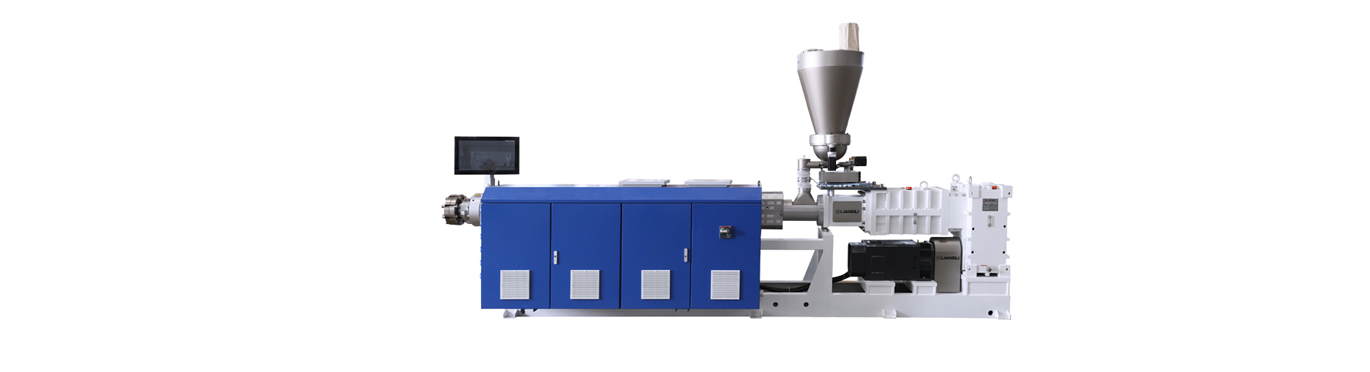

Permanent Magnet Servo Motor

The extruder is equipped with “Hengpu” permanent magnet servo motor specially designed for twin-screw extruder, which has high-output and low energy consumption and the energy consumption per unit of the whole line is 0.06~0.08kwh/kg, and the production capacity is 12kg/kw.

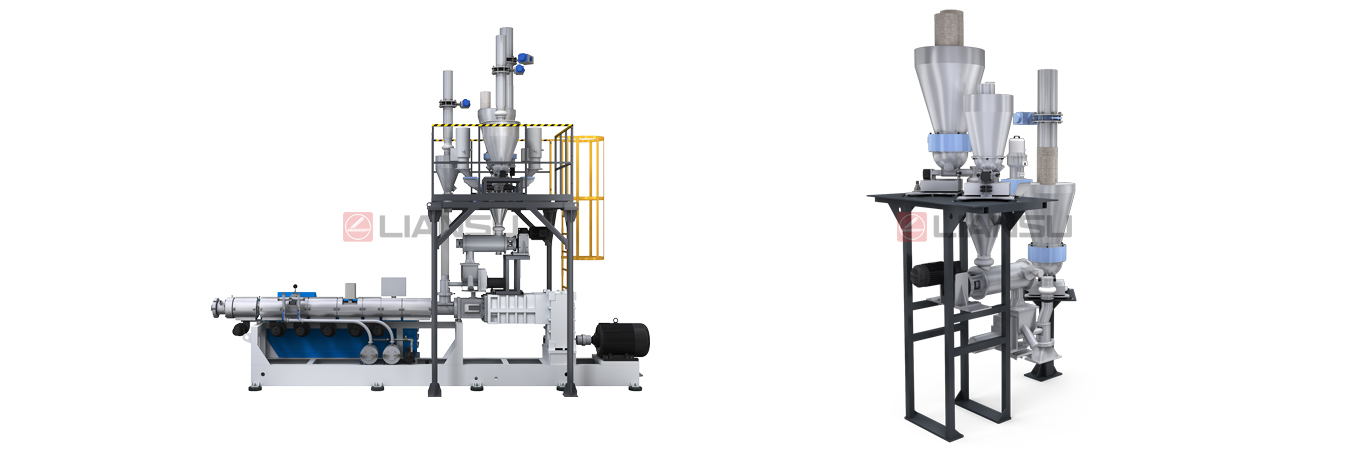

Loss in weight Feeder

A brand of LIANSU ,Mconvey,a professional supplier and offering full range of dosing and gravimetric device for different type of plastic material. The loss-in-weight feeders specialized for PVC compound materials, on line accuracy control meter weight of pipe , and contribute flexible formula on line change , with patent designed on bridge breaking and anti-flushing , ensuring different type of material accuracy weighing and dosing on line and stable feeding, reducing raw material consumption and lower production costs.

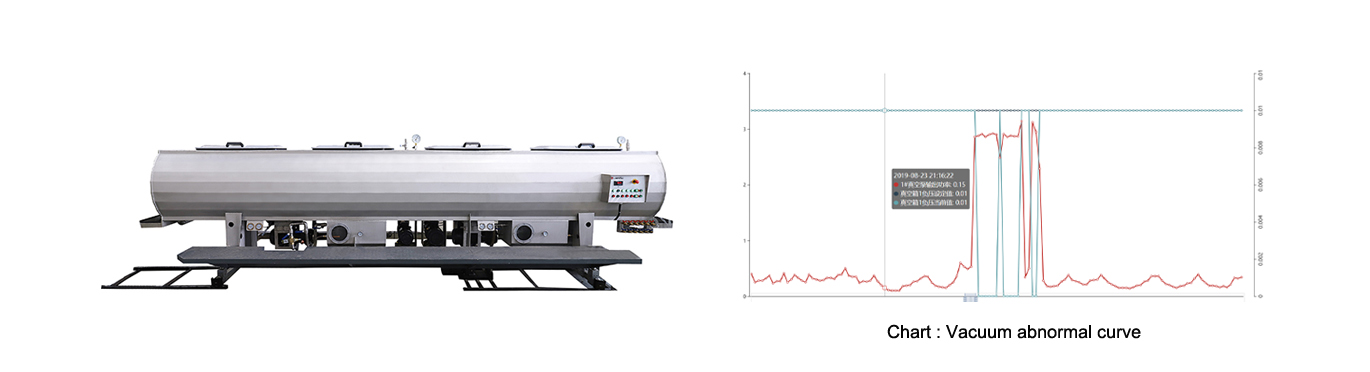

Closed- loop Vacuum control

The automated negative pressure closed-loop control system can ensure pipe rapid forming, fast dynamic response, and real-time detection of vacuum leakage and automatic compensation, making vacuum forming more stable. In addition, the automatic adjustment of vacuum pump speed can reduce the noise of vacuum tank and save energy over 50%.

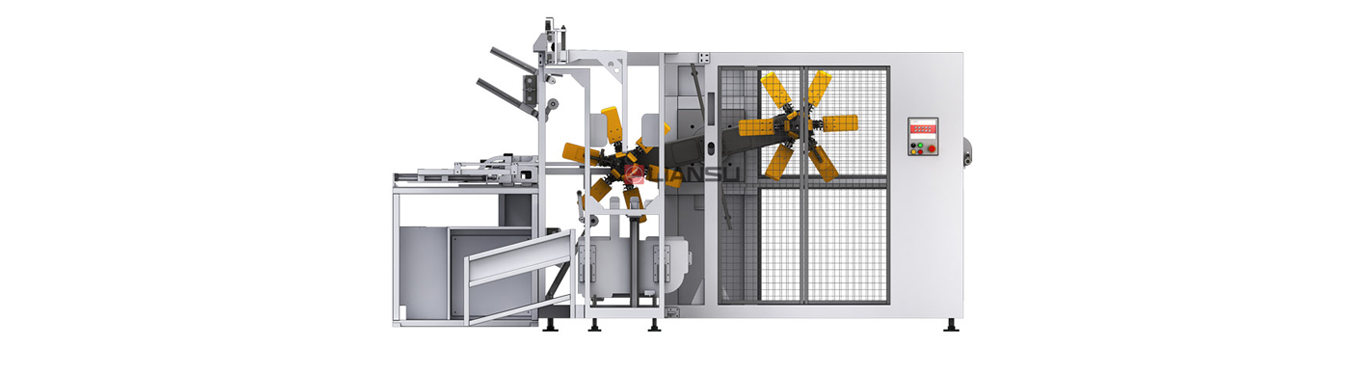

Weighing stacker

In order to control accuracy weight of each pipe,and collect the qualify pipe data, LIANSU devleoped the pipe weighing stacker to accurately control pipe weigh and numbers to acheive better quality control and data application integrated to Flexcon control or IOT sytem. It greatly reduce manual operations and improve production efficiency.

Automatic Coiler

Liansu provides full range of automated pipe coiler and online packaging equipment, which automatically completes pipe coiling,bundling and packaging,unloading. It can meet the production speed of 60m/min, and provide various solutions according to different speeds of the production line, reduce manpower cost.