LIANSU has developed an efficient and energy-saving Permanent Magnet "Two-Stage" Vacuum Pump Station for material conveying. This system can directly connect a Roots vacuum pump with a highly efficient permanent magnet motor,ensuring large and stable vacuum flow and energy storage. One vacuum station can replace multiple traditional Roots vacuum pumps units , which can effectively reduce the energy consumption, lower maintenance rates, and operate with low noise.

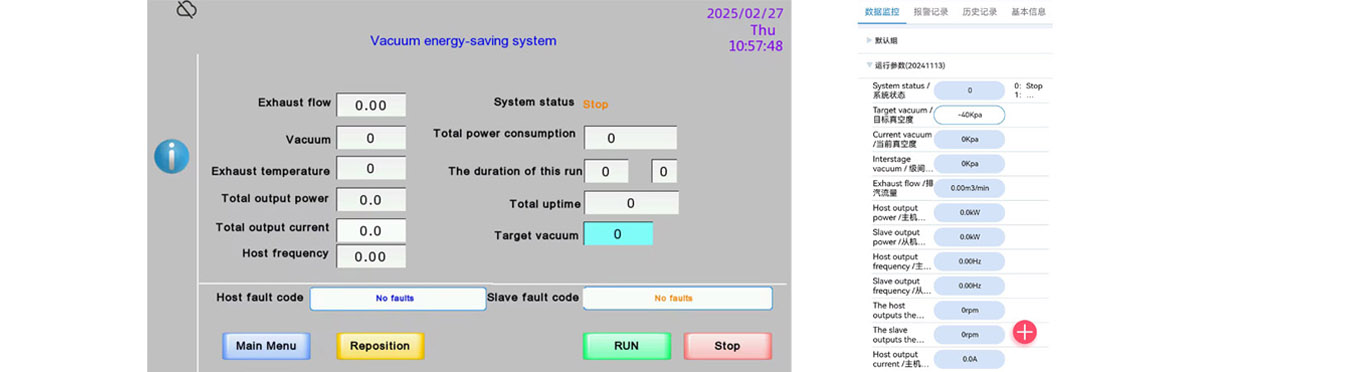

The vacuum pump station adopts permanent magnet variable frequency motor direct drive with efficient cooling and low-frequency pressure maintenance. The body temperature is lower than 60℃, with fast response, high efficiency, low noise, and long life. With the intelligent centralized dust collector, it supports automatic or manual switching of filters, and the filter element is easy to replace without affecting use, and reduce 1/3 area . The system adopts PLC control and intelligent monitoring, records working data in real time, supports APP monitoring, and prevents and maintains in advance, and quickly solves faults.

It can be widely used in material negative pressure conveying, vacuum packaging, vacuum forming, paper making, food containers, and plastic vacuum shaping (such as plastic pipes and profiles) and other industries. With LIANSU Permanent Magnet Vacuum Pump Station , the material handling in injection molding workshops can save over 50% energy compared to traditional multiple Roots vacuum pumps. In centralized vacuum forming for plastic profile extrusion, it can save over 40% energy compared to single machine turbine water tank groups and in centralized vacuum shaping for plastic pipes, it can save 40-50% energy compared to single machines.