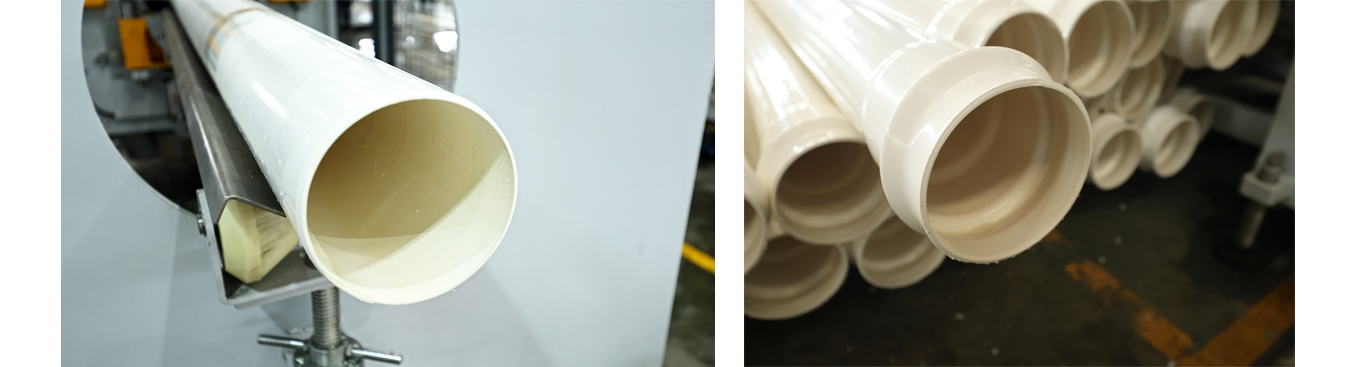

LIANSU uses online production technology to realize biaxial directional pipe manufacturing. The production line is equipped with specially designed and optimized professional equipment for the production of PVC-O pipes, including: extruder and pipe head, vacuum tank, haul off unit, oven, heating furnace, stretching device, cutting machine and online socket machine. The production line provides full-process integrated control system.

LIANSU offers production lines to produce pipes that comply with ISO 16422 or with required national standards. LIANSU production lines can be tailored to produce product, strength up to MRS 500. Pressure classes up to PN25. The lines can also be tailored to produce product at lower MRS and pressure classifications.

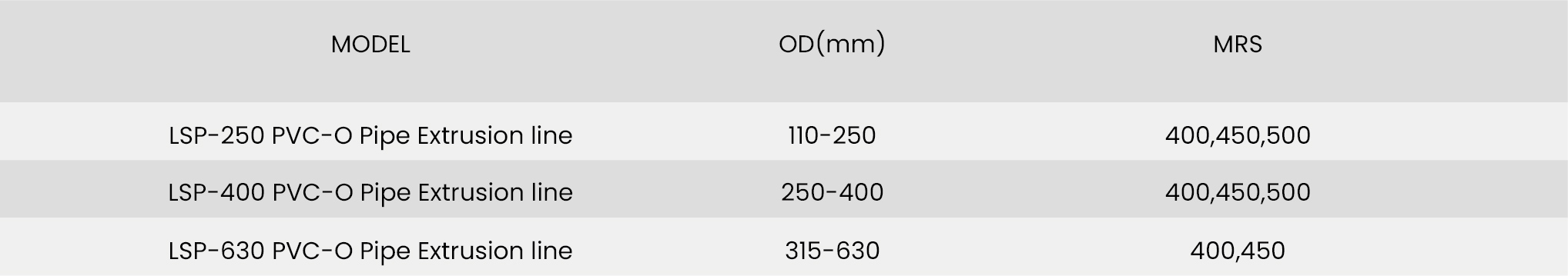

Size range(mm)

Brochure Download

Brochure Download