2025-05-26

2025-05-26

1333

1333

Liansu Extrusion

Liansu Extrusion

LIANSU developed full range of PVC-O pipe extrusion line. Completed line design focuses on stable product performance and intelligent control, providing users with a complete solutions for closed-loop production from raw material dosing to cutting and online socket.

PVC-O Extrusion

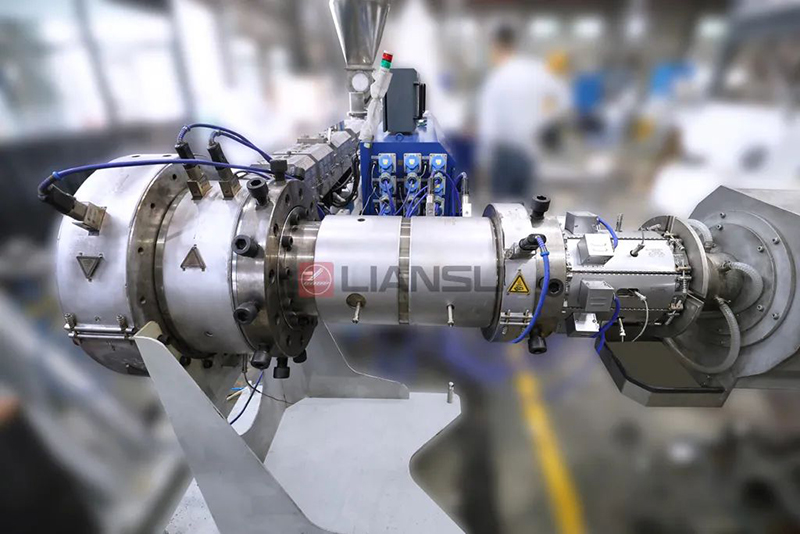

Extruder adopts 36L/D parallel twin screw design, dedicate designed for efficient plasticization of PVC-O compound materials. Screw structure is optimized to improve mixing uniformity and ensure melt stability.

Pipe Head

Pipe head adopts a double compression structure design to ensure the melt viscosity and temperature more uniform, optimize flow channel distribution, effectively eliminate melt line, and improve the physical strength of the pipe. The temp. control of pipe head adopt independent zoned temperature control, pratical adjusting and control the thickness of pipe.

Vacuum tank

Tank adopts a single-chamber design, equipped with a high-efficiency filtering device and precise water level and water temperature automatic control system to achieve continuous and stable shaping process.

Oven: Accuracytemperature control

Temperature control chamber adopts a combined design of hot air and infrared heating to ensure uniform temperature distribution along the circumference and wall thickness of pipe.

Haul off

It adopts servo control, which is stable and efficient. Each section cooperates according to the process requirements, and has structural advantages such as synchronous clamping and double caterpillars reinforcement design, ensuring that the pipe can be stably transported and strongly pulled at different stages, meeting the needs of complex working conditions such as thin-wall and expansion molding, and effectively improving molding quality and production efficiency.

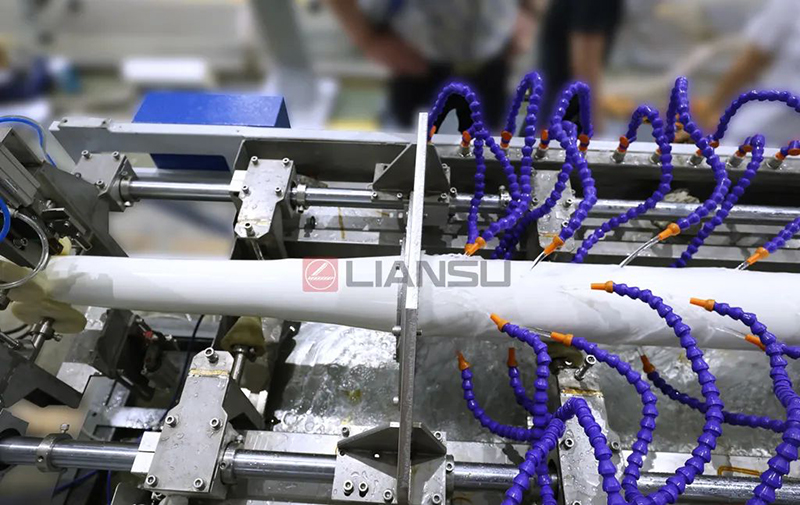

Orientation

The orientation expansion tool adopts air expansion mechanism to achieve "low friction expansion and stretching" between the inner wall of the pipe and tooling, and cooperates with the circulating water cooling system to quickly cool the forming while reducing friction resistance, improve the smoothness of the inner wall, and improve the consistency of the finished product.

Planetary Cutter

Servo-controlled planetary cutting, and the chamfering mechanism adopts centrifugal force balance principle, which especially ensures uniform chamfering of thin-walled pipe.

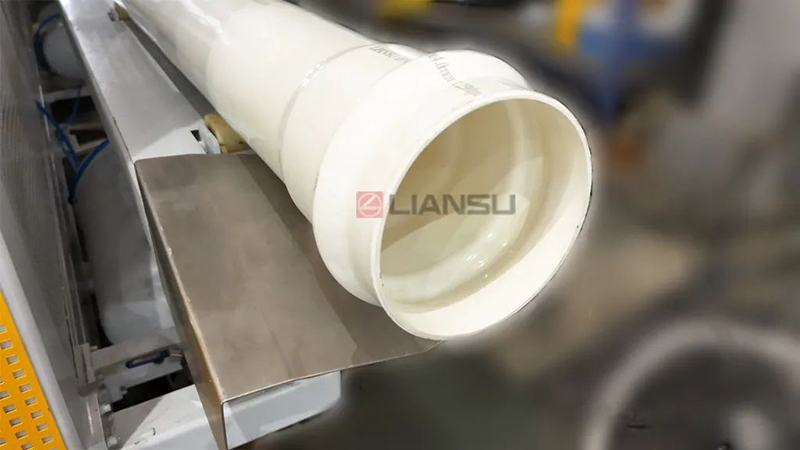

Online socketing machine

Online socketing machine adopts an integrated heating and socketing structure design, with a compact overall layout and a small footprint, which is conducive to production line integration and space utilization efficiency.

It adopts uniform heating mode, which can continuously maintain pipe end temperature during socket, so that the PVC molecular chain can be fully oriented in the axial and radial directions, avoiding shrinkage or deformation caused by temperature difference or stress.

Fast socketing to ensure consistency of size and shape, which improve the overall strength, toughness, impact resistance and fatigue resistance of pipe.

PVC-O Pipe

LIANSU's PVC-O pipe extrusion line with completed configuration , convenient operation, and intelligent control, which can meet the production needs of PVC-O pipes in different specifications and application. This production line can be widely used in municipal water supply, gas transmission and industrial pipelines, helping customers to achieve both product quality improvement and production line efficiency optimization.

Welcome to contact us:

+86-18028101014

for more info !